Health and Safety

Financial Benefits | Environmental Benefits | Health & Safety | Durability | Comfort & Quiet | FAQs

Fire Resistance | Wind Resistance

ICF concrete structures provide superior resistance to fires, natural disasters, insects, and mold.

The concrete core in ICF walls resists damage from wind, fire, earthquakes, termites, rot, mold and mildew like no other wall system can. Not only does this result in lower maintenance and insurance costs, but risks to life and threats to business continuity are greatly diminished, so ICF-built structures hold their value for generations.

Not only do ICF buildings offer significant up-front and ongoing economic advantages, they are quieter, more comfortable, safer and environmentally considerate. Because sound penetrates ICF walls only 1/8 to 1/4 as much as conventional walls and because an unbroken exterior envelope results in fewer cold spots and drafts, ICF structures provide a more comfortable interior environment. Plus, concrete’s strength and durability helps protect occupants from crime and natural forces, ICF structures have health advantages as well. With ICFs, exposure to manufactured wood products is greatly reduced, thereby minimizing exposure to harmful volatile organic compounds (VOC) and off-gassing, while mold resistance reduces health concerns.

ICF components are lightweight: Forms go up faster and with fewer safety concerns as compared to other wall systems. Reduce worker injuries with lightweight materials and profit from cleaner, quieter and more comfortable interiors.

Fire Resistance

Fire Resistance of Concrete Buildings

Of all the construction materials, concrete is one of the most resistant to heat and fire. Such fire resistance gives ICF buildings certain safety advantages. These advantages provide builders and buyers with yet another reason to consider using ICFs for their next project.

Do ICF walls stop fire from spreading?

Concrete walls have also proven more resistant to allowing fire to pass from one side of the wall to the other. This is especially of interest in areas with brush fires that could spread indoors.

The fire wall test confirms this rule for ICFs. Part of the test measures how well the wall slows the passage of heat and fire from the side with the flame to the other side. In tests, the ICF walls did not allow flames to pass directly through. It also took 2-4 hours before the ICF walls allowed enough heat through to start a fire on the cool side. In contrast, wood frame walls typically allow both flame and fire-starting heat through in an hour or less.

Does the foam in ICFs add fuel to the fire?

The foams in ICFs are manufactured with flame-retardant additives. These prevent the foams from burning by themselves. If you hold a match to the material, it will melt away.

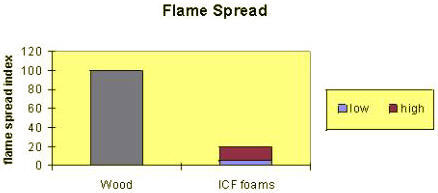

Of course, in a house fire, the foam may be subjected to constant flame from other materials burning nearby (wooden floors, fabric, etc.). The “Steiner Tunnel Test” measures how much a material carries fire from an outside source. In the test, technicians line a tunnel with the material, run a fire at one end, then measure how far the flame spreads. The flames travel about one-fifth as far down a tunnel lined with ICF foams as they spread down a tunnel lined with wood.

Can the foam give off harmful emissions?

Practically any organic material, be it wood or plastic, gives off emissions when it is subjected to intense heat or flame. The Southwest Research Institute reviewed the numerous existing studies of fire emissions and concluded that the emissions from polystyrene foams are “no more toxic” than those of wood.

What precautions should I take to make my house fire resistant?

No matter what your walls are made of, there is no sense in playing with fire. Building codes require that the inside face of exterior walls be covered with a fire-resistant material, such as gypsum wallboard or a stout plaster. In areas prone to outdoor fires, it is wise to finish the exterior with a fire-resistant material, as well. Favorites are Portland cement stucco and masonry. The more that a building can be designed to limit the exposure of flammable materials such as wood and fabric, the better.

What's the bottom line?

Evidence suggests that in the event of a fire, ICF walls may be safer in many ways than wood-frame. Using ICF walls provides an important and effective measure of fire safety.

Wind Resistance

Concrete provides built-in safety.

Debris driven by high winds presents the greatest hazard to buildings during tornadoes and hurricanes. Recent laboratory testing at Texas Tech University's Wind Engineering Research Center compared the impact resistance of residential concrete wall construction to conventionally-framed walls. The frame walls failed to stop the penetration of airborne hazards, while the concrete walls successfully demonstrated the strength and mass necessary to resist the impact of wind-driven debris.

What was tested?

Various wall specimens were subjected to the impact of a 2x4 wood stud traveling at up to 100 miles per hour. This is equivalent to the weight and speed of debris generated during a tornado with 250 mile-per-hour winds. This testing covers the maximum wind speed generated in 99 percent of the tornadoes occurring in the United States. Wind speeds are less than 150 miles per hour in 90 percent of tornadoes.

Ten wall specimens were constructed, each representative of the type of construction now used to build frame homes and concrete homes in the U.S. Tables 1 and 2 describe each wall assembly tested.

The Wind Engineering Research Center used a compressed air cannon to propel the wood stud debris "missile" at the test walls. The stud was propelled along its axis with the leading end hitting the specimen. Electronic timing devices measured the speed of the debris as it traveled from the cannon to the test walls located 16’ to 6" away.

How did the frame walls perform?

The frame walls lacked the weight and mass to resist the impact of the wind-driven debris. In each case, the debris traveled completely through the wall assembly with little or no damage to the "missile."

Table 1: Frame Wall Test Results

|

How did the concrete walls perform?

The concrete stopped the debris from traveling through the wall. Exterior finishes were damaged by the impact, but the concrete walls themselves remained unscathed. Even the narrowest, 2" thick section of "waffle grid" ICF wall was undamaged by the direct impact of the debris at over 100 mph.

Table 2: Concrete Wall Test Results

|

Note:

All concrete tested: 3000 PSI compressive strength, maximum aggregate size ¾", 6" slump.

What about damage from hurricanes?

Hurricane wind velocities would be less than the equivalent maximum speeds modeled in these tests. Missile testing designed to mitigate property damage losses from hurricanes uses a 9-pound missile traveling about 34 mph as criterion.

What's the bottom line?

The strength and durability of concrete walls formed with ICFs offer unmatched resistance to the devastation of major storms. Concrete buildings are less likely to suffer major damage from debris than conventionally-framed structures. This greater measure of built-in safety makes ICF construction the quality choice for your building.

More Information?

The following publication and video are available from the Portland Cement Association:

VC511 Concrete Homes: Built-In Safety ($4.95)

Videotape documenting the results of the wind-driven debris impact testing. All

ten of the impact tests are featured.

RP122 Investigation of Wind Projectile Resistance of ICF Homes (June 1998)

Written report with photos detailing the results of the wind-driven debris impact

research. Background information on the critter and assumptions used to

generate the test design are included.

To order, call PCA Publications at 1-800-868-6733.